HEXAGON, the global leader in digital reality solutions, has unveiled the release of HxGN Production Machining, a new suite of software developed to empower machine shops to achieve operational excellence in the manufacturing of discrete parts, tools and components.

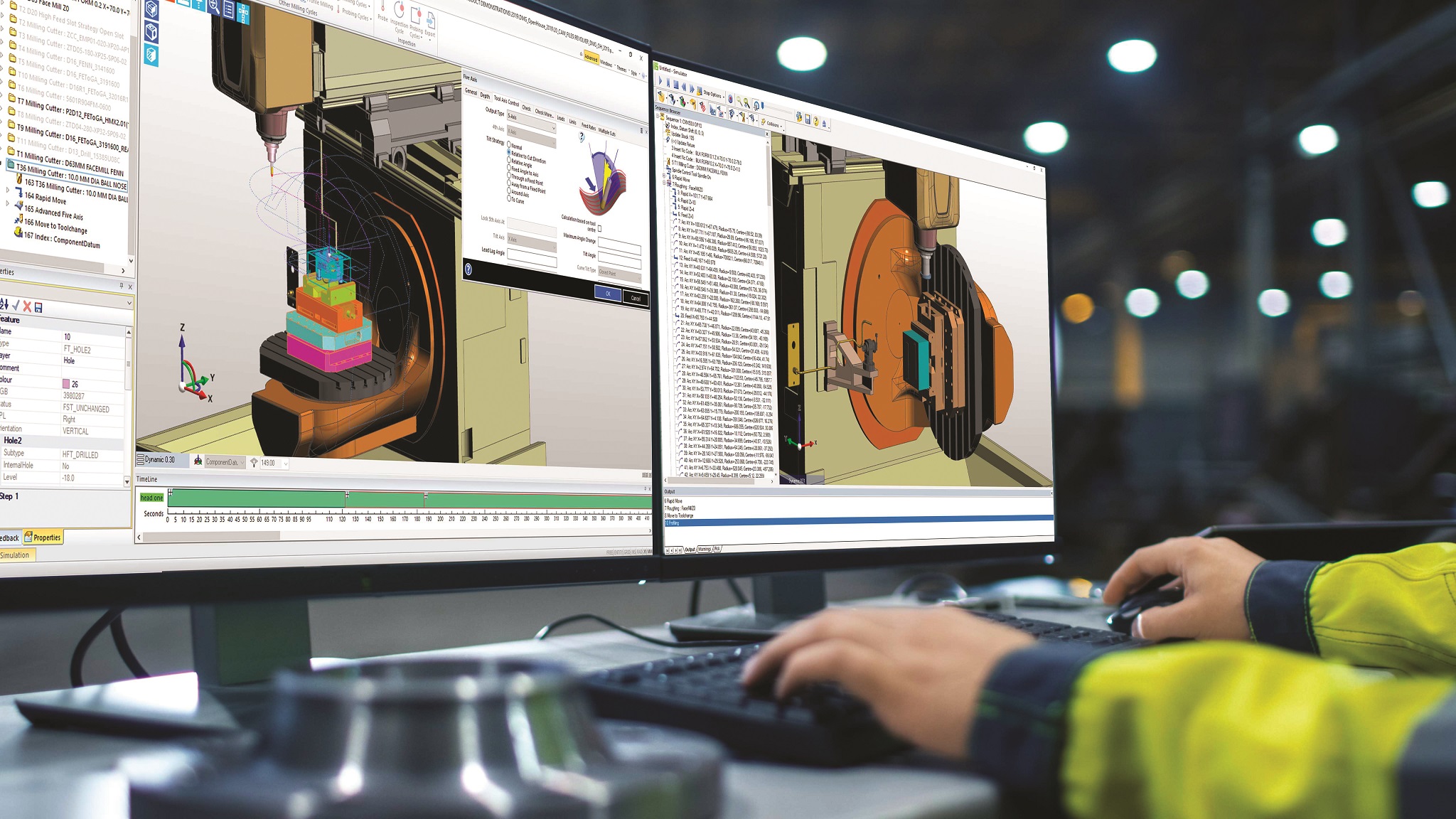

Capabilities of the suite include CAD (computer-aided design) for manufacturing and design review, CAM (computer-aided manufacturing) for CNC (computer numerical control) machine-tool programming, process simulation, and G-code verification and optimisation.

Central to the company’s Machine Shop Excellence solutions, the suite includes significant automation and innovative technologies that help manufacturers achieve highly efficient utilisation of material, cutting tools and CNC equipment.

The HxGN Production Machining suite will integrate common workflows to help teams reduce error and eliminate redundant tasks at every stage – from job quotation and design review through production, quality assurance and product delivery.

By offering a suite of connected products from the Hexagon ecosystem, manufacturers benefit from simplified procurement, implementation and support. The suite’s flexibility makes it suitable for shops of any size, all types of CNC machinery, and any discrete part and material from one-off prototype to high-volume production runs.

“The HxGN Production Machining suite helps shops of all sizes run their businesses more productively by providing a robust software tool set within a connected and intelligent digital workflow that helps teams get it first-time right,” shared Hexagon’s general manager (production software) Chuck Mathews.

“Using the principles of model-based manufacturing and the automation benefits of artificial intelligence (AI), we are helping our customers achieve greater operational excellence.”

Added Mathews: “Innovations within the suite include our new CAM system, ESPRIT EDGE which combines the DNA of Hexagon’s EDGECAM and ESPRIT software with powerful digital twin and AI technology.”

Meanwhile, Hexagon’s chief product & technology officer Parth Joshi said through its HxGN Production Machining suite, Hexagon is able to re-focus innovation on what matters most to customers, be that in single product or leveraging data across workflows.

“Our cloud-based Nexus platform supports future developments that will simplify collaboration and consolidate job data so teams can improve efficiency and quality as they run jobs through their shops from quote through final delivery,” he added. – Sept 25, 2023