HEXAGON, the global leader in digital reality solutions, has released HxGN Mould & Die, a suite of dedicated CAD/CAM (computer-aided design and manufacturing), engineering and automation tools which enable manufacturers to increase efficiency, reduce costs and produce high quality tools for their customers across industries ranging from automotive to aerospace and beyond.

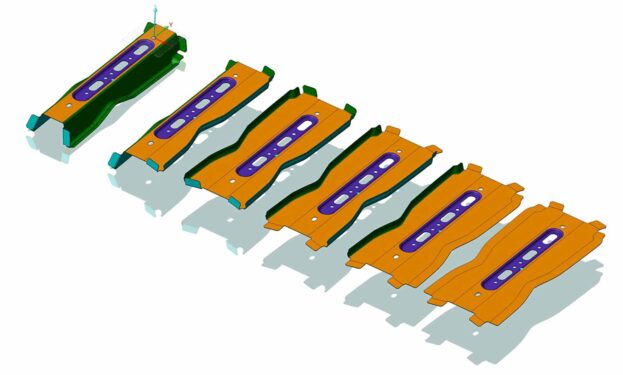

The suite was developed to empower mould designers and makers to achieve operational excellence in the design and manufacturing of plastic injection moulds, progressive dies, forming dies, and similar tools.

Capabilities of the suite include CAD/CAE (computer-aided design and engineering) for plastic injection mould design, CAD/CAE for progressive die design, CAD for manufacturing preparation, CAM for CNC (computer numerical code) machine-tool programming, process simulation and G-code verification and optimisation, shop-floor production intelligence, and automation and collaboration powered by Nexus which is Hexagon’s digital-reality platform.

The suite’s simulation tools help manufacturers understand the feasibility and cost of mould-making processes with actionable information.

“We took everything we know about mould-and-die manufacturing, including our best-in-class Hexagon technologies, to build a specialised suite that empowers mould and die shops of any size to get the best results faster,” shared Hexagon’s general manager (production software) Chuck Mathews.

“Their competitive edge will be enhanced Nexus which connects desktop software via the cloud to provide further automation and collaboration opportunities. It also gives teams an easy way to share 3D models with customers through secure web-based visualisation and consolidate access to libraries for tooling, fixtures and materials from their desktop apps.”

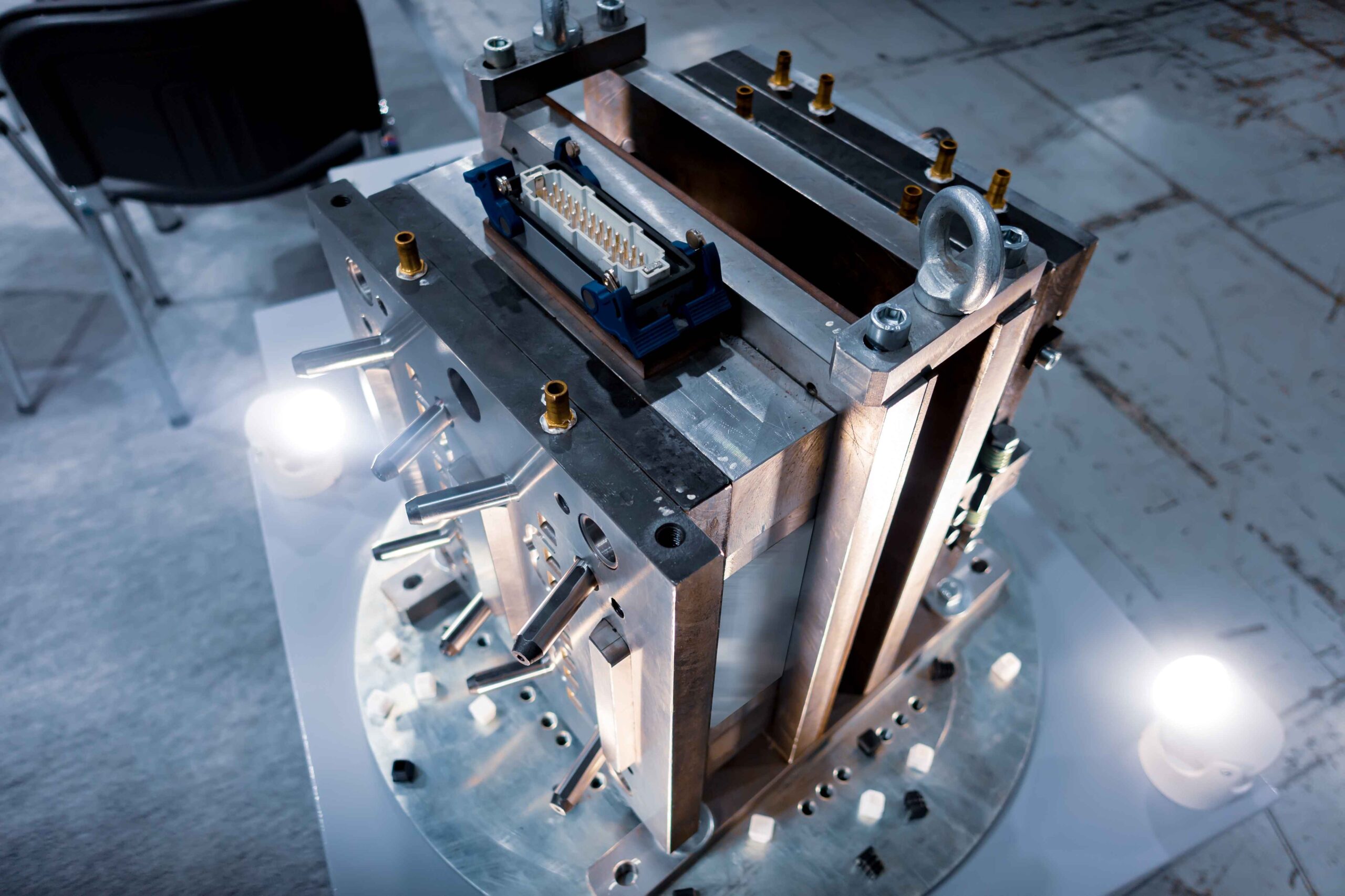

For plastic-injection mould manufacturers, the suite provides tools for design and engineering, flow simulation, reverse engineering, automated electrode design and CNC machining.

It builds upon Hexagon’s market-leading VISI and WORKNC software, providing comprehensive multi-axis CAM programming capabilities, direct modelling of solids and surfaces, and supports the construction, editing and repair of complex 3D geometry.

Reverse engineering tools allow mould makers to efficiently create solid models from scanned data – a crucial capability for mould repair and redesign, and for creating solid models for manufacturing when CAD files are not available. – Oct 15, 2023